Timing Kit Set

What is Timing Kit Set?

GLOBELT TIMING KIT SET is specially design for the convinence of customer when comes to the time for regular replacement of the component. It consists of GLOBELT TIMING BELT, TIMING BEARING and OIL SEAL, this prefix set of component will help you to be hassle free in changing of timing belts or any other relevant components.

Some repair jobs go hand in hand and it just makes sense to do them together. Timing belts and timing bearing are just such an example. We've gone even further with this kit and included all engine oil seals to complete the kit.

Components in Timing Kit Set

Basic

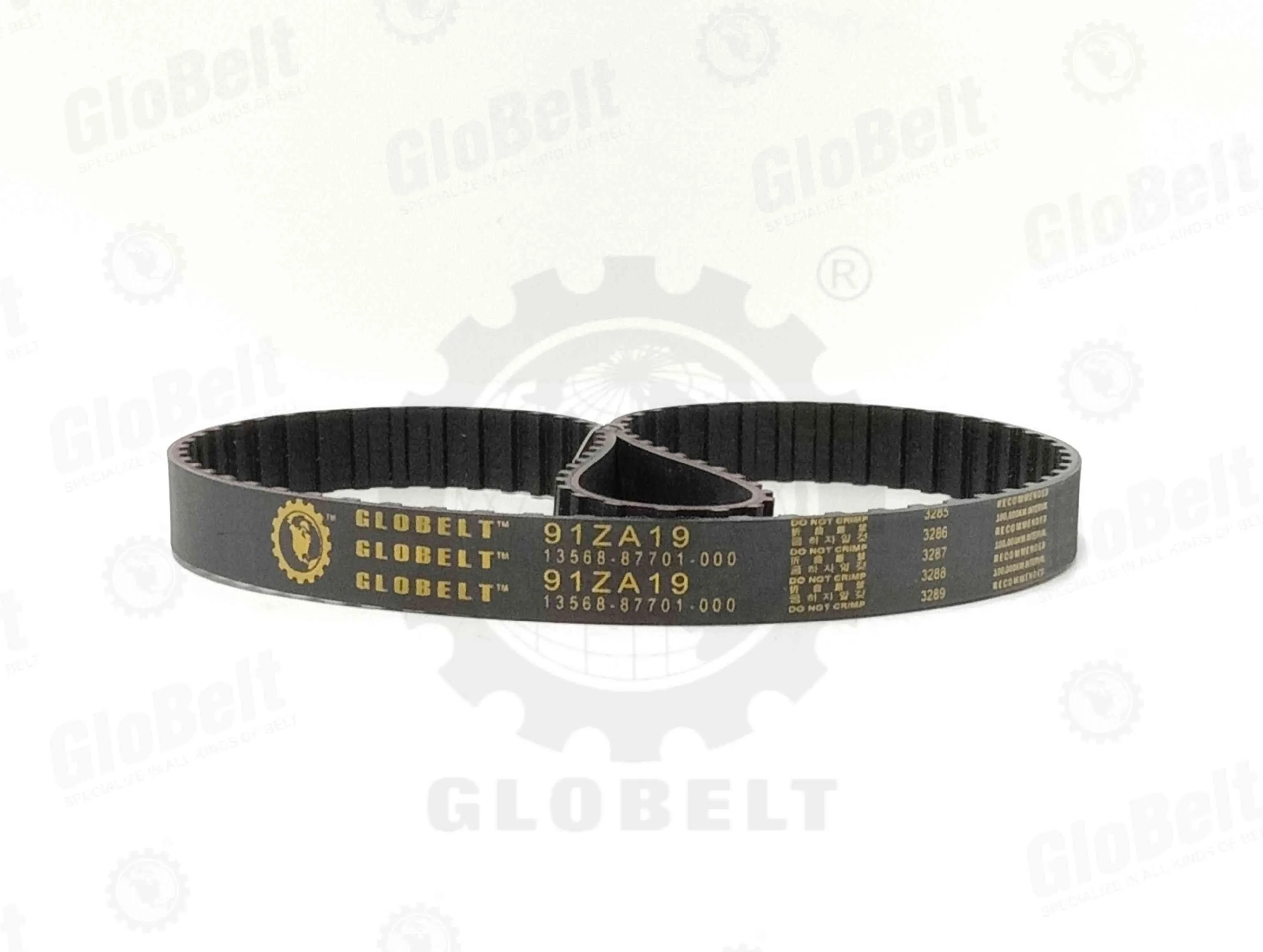

Timing Belt

GLOBELT Timing Belt is manufactured with high quality, temperature and contamination resistance Hydrogenated Nitrile Butadiene Rubber (HNBR)

Hydrogenated Nitrile provides excellent resistance against motor oil, gas, oxidized fuels as well as lubricating oil deterioration. It is also highly resistant to animal and vegetable fats, fuel, Ozone, solvents and dilute acids. Aside from providing outstanding resistance and stability, hydrogenated nitrile also provides superior tensile and tear strength properties. This combination of properties enable you to use our material in a broad range of applications and environments.

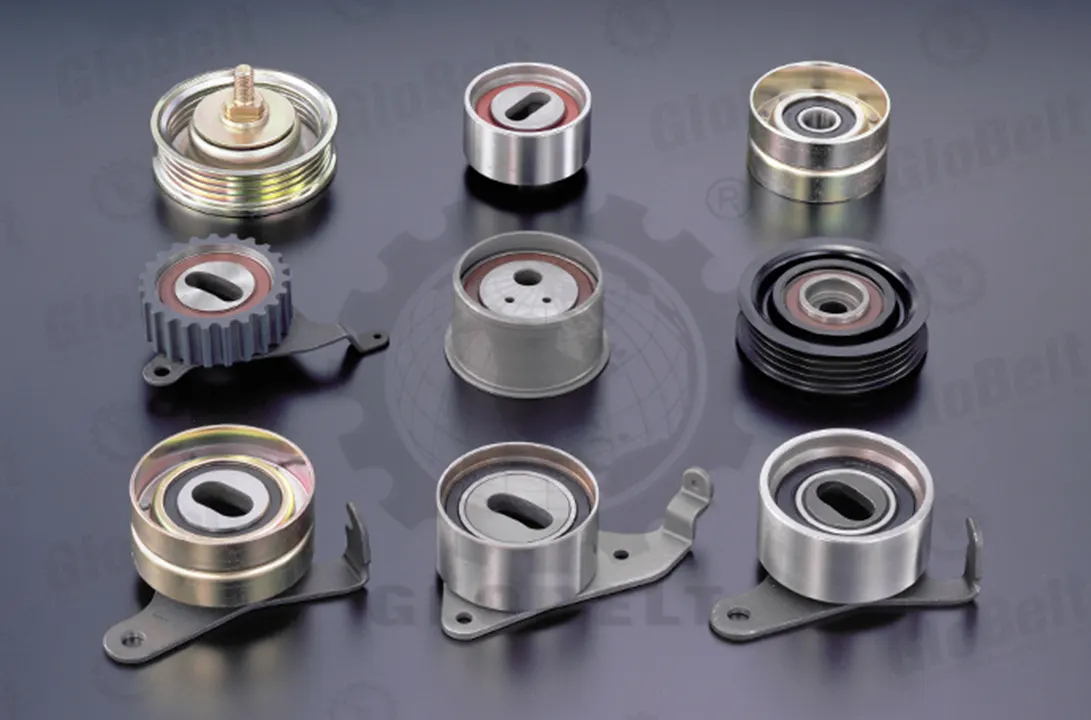

Timing Bearing

Timing BearingorTensioner and Idler Bearingconsists of basic components like inner ring, outer ring, retainer, grease and seal. These are used in the timing belt and auxiliary drive belt to adjust the belt tension or change the belt running path.

Oil Seal

Oil Seal originally sourced from VITON, which well-known for its high temperature resistance.

VITON (rubber and fluoropolymer specialist) is a synthetic rubber and fluoropolymer elastomer used in O-rings, seals and other moulded products. Genuine Viton® is manufactured from 100% pure fluoroelastomers and is certified with the Viton® certificate .

Specific

Specific Component - all the components of current section only included in some specific car model.

Oil Pump Belt

GLOBELT Oil Pump Belt is manufactured with high quality, temperature and contamination resistance Hydrogenated Nitrile Butadiene Rubber (HNBR)

Hydrogenated Nitrile provides excellent resistance against motor oil, gas, oxidized fuels as well as lubricating oil deterioration. It is also highly resistant to animal and vegetable fats, fuel, Ozone, solvents and dilute acids. Aside from providing outstanding resistance and stability, hydrogenated nitrile also provides superior tensile and tear strength properties. This combination of properties enable you to use our material in a broad range of applications and environments.

Oil Pump Bearing

Oil Pump Bearing consists of basic components like inner ring, outer ring, retainer, grease and seal. These are used in the timing belt and auxiliary drive belt to adjust the belt tension or change the belt running path.

Function of Timing Belt, Timing Bearing & Oil Seal

Basic Component

Timing Belt

Timing Belts are one of the most important moving parts in your engine that helps the vehicle engine run smoothly by connecting the camshaft and crankshaft. The crankshaft assists the pistons in moving up and down.

A timing belt is a toothed belt which keeps the top half of the engine (the cylinder head and valves) aligned and synchronised with the crankshaft and pistons in the bottom of the engine. This then allows the values and pistons to move in harmony with each other. They drive, among other things, a water pump, a generator and a power-assisted steering pump. If any of these components stop working, your vehicle can face serious, costly problems, from loss of engine coolant to engine seizure.

Highlights

Timing Belt ensures precise synchronize opening and closing of the engine’s valves.

It connects the crankshaft and the camshaft together to control the valve operation.

Some other engine components such as water pump, injection pump, and oil pump.

The timing belt uses the same combustion mechanical energy to control the valve. This means no external source is included.

Another function of a timing belt or chain is that it prevents the piston from striking the valves on a critical level.

A timing belt is just a single device but connects different parts such as the camshaft sprocket, timing belt idler pulley, upper balance shaft sprocket, water pump pulley, timing belt tensional roller, balance idler roller, lower balance shaft sprocket, camshaft belt drive gear, balance belt drive gear, and balance belt tensioner roller.

Timing Bearing

Timing Bearing also known as tensioner bearing used to adjust the belt tension or change the belt running path. Because the bearings are mounted on the engine, they have to be reliable in high-speed rotation and high temperatures.

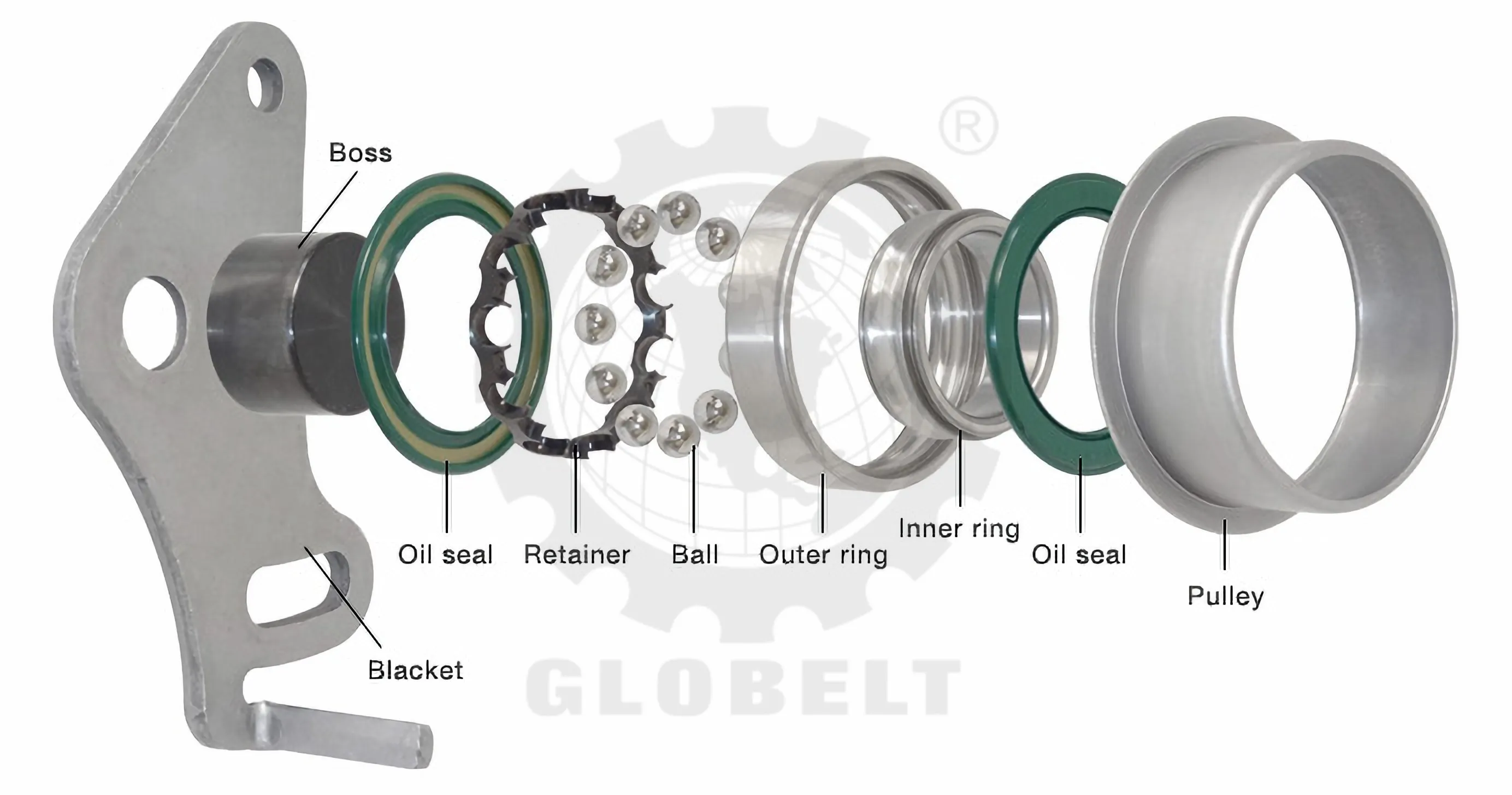

Timing Bearing or tensioner and idler bearing consists of basic components like inner ring, outer ring, retainer, grease and seal. Pulley may be added to adjust rotation ratio. Bracket may be added to adjust location for adding tension. Races are one of the bearing component parts. It has grooved track for balls to locate. Outer race and inner race make a set. Inner race is situated on sub-assembly unit and outer race is set on housing. Pulley may be added on outer race to provide timing belt system with designed revolution rate. Rolling element is "ball" running between races. Retainer moving along with balls separates individual ball into position. Also grease has important role to reduce friction and oil seal serves to hold grease and shut foreign particles from intrusion.

Highlights

To provide belt with tension.

To transfer driving force from crankshaft.

To prevent belt slippage.

To prevent noise caused by off-line belt.

To minimize space of belt layout.

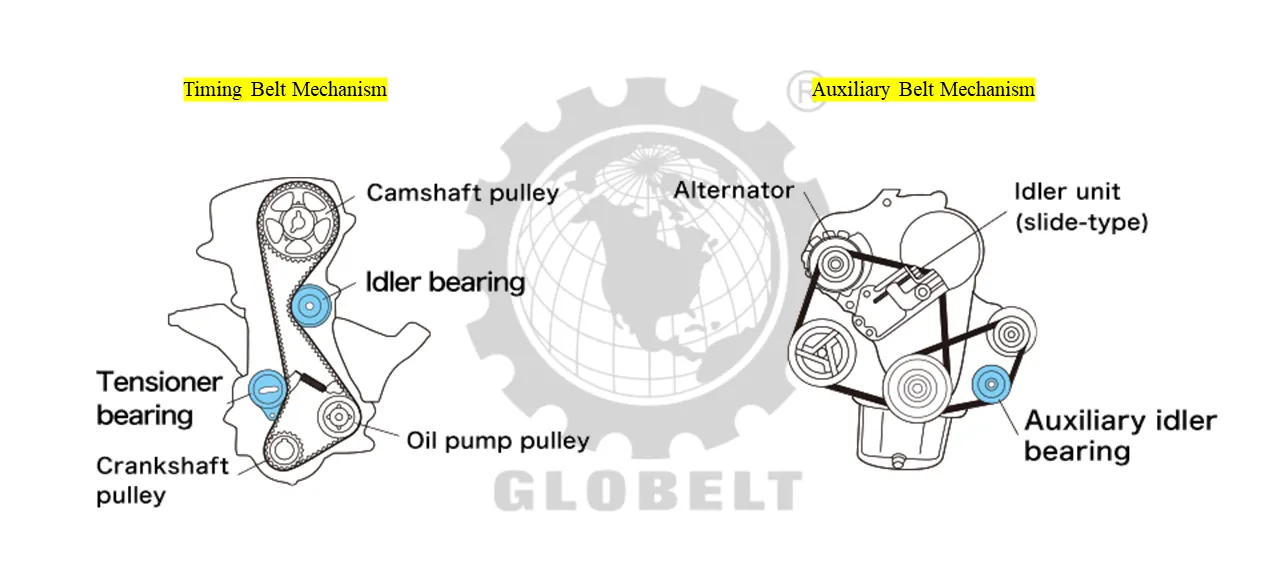

Different between Tensioner Bearing and Idle Bearing

The timing and auxiliary belts are equipped with idler bearings with pulleys and brackets attached to them. In the timing belt mechanism, the type with a slotted hole in the inner ring or a bracket for tension adjustment is sometimes called the tensioner bearing, and the type without an adjustment mechanism is sometimes called the idler bearing.

Timing Belt driven outer ring mechanism is inherent in this design. Tensioner bearing is placed at slack side while Idler bearing at tight side. There are various styles according to engine types.

Timing Belt Mechanism & Auxiliary Belt Mechanism

A car's engine includes both :

A timing belt mechanism that drives the camshaft, oil pump, etc.

An auxiliary drive belt mechanism that drives the auxiliary machines such as the alternator, air conditioner, and water pump

Oil Seal

Oil seals, often called a rotary shaft seal or grease seal, closes the gap between stationary and moving components in mechanical equipment (most often rotating shafts), helping prevent lubricant escape and stopping harmful materials, such as dirt, from moving in through the clearance. Oil seals are most commonly used in gearboxes, hydraulic cylinders, and related components.

It plays a key role in all moving parts of an engine, acting as a physical barrier. This mechanical seal fulfils the dual purpose of sealing a rotary shaft to maintain the necessary lubrication (avoiding leaks) and preventing other foreign matter from contaminating shafts and bearings in the rotary shaft equipment.

Highlights

To prevent lubricants from leaking outside the seal even under high pressure.

To act as a barrier to retain the lubricating oil.

To prevent dirt and other contaminants from entering the unit.

Characteristics of Oil Seal

A. Nose gasket prevents leakage through the seal O.D.

B. Lip design with excellent followability.

C. Linear contact type sealing adge with high durability under high peripheral spped.

D. Rubber material with high self-lubricating property.

Specific Component

Oil Pump Belt

Oil Pump Belt is used for oil pump drives and camshaft and crankshaft timing and, due to the innovative materials used in BIO systems, these belts are more temperature-resistant, stretch than conventional dry belts and more durable. In addition, being made of rubber, in contact with metal it is quieter than a timing chain.

With the increasing demand for higher engine performance, the Oil Pump Belt, also known as ‘Belt in Oil’, is narrower and quieter than dry belts and its main characteristic is that it is housed inside the engine, in the lubricated area, with a hermetic metal cover.

Highlights

Better engine performance.

Reduced emissions.

Low operating noise.

Reduced fuel consumption and energy losses.

Oil Pump Bearing

Similar to timing bearing, Oil Pump Bearing used to adjust the belt tension or change the belt running path. Because the bearings are mounted on the engine, they have to be reliable in high-speed rotation and high temperatures.

Oil pump bearing consists of basic components like inner ring, outer ring, retainer, grease and seal. Pulley may be added to adjust rotation ratio. Bracket may be added to adjust location for adding tension. Races are one of the bearing component parts. It has grooved track for balls to locate. Outer race and inner race make a set. Inner race is situated on sub-assembly unit and outer race is set on housing. Pulley may be added on outer race to provide timing belt system with designed revolution rate. Rolling element is "ball" running between races. Retainer moving along with balls separates individual ball into position. Also grease has important role to reduce friction and oil seal serves to hold grease and shut foreign particles from intrusion.

Highlights

To provide belt with tension.

To transfer driving force from crankshaft.

To prevent belt slippage.

To prevent noise caused by off-line belt.

To minimize space of belt layout.

Warning Signs - Maintenance & Replacement

How does Timing Belt break?

The timing belt break more often because of a lack of understanding and maintenance. The timing belt is made of rubber, when the engine is very hot, it naturally degrades the strength and texture of the belt, resulting in the belt breaking. Therefore, the timing belt should be changed or replaced according to the manufacturer’s recommended maintenance schedule.

Another cause of the breakdown of the timing belt component is a seizure of the water pump, which is caused by insufficient maintenance of the cooling system . When the water pump gets stuck, the gears stop instantly, which automatically causes the belt to break.

Maintenance & Replacement of a Timing Belt

It is very important for your vehicle to replace the timing belt at the mileage intervals recommended by the vehicle manufacturer. The recommended interval for timing belt replacement of your specific vehicle can be found in your vehicle’s manual.

Since the timing belts are made of rubber, they will wear out over time and eventually break. When it breaks down, the engine breaks down, components will be out of sync, and the engine will stop running. Failure to replace the timing belt or timing chain at the recommended time can result in engine failure, piston and cylinder wall damage, cylinder head or camshaft damage, and valve breakage or bending . This is not a situation in which you can confidently think, “If it’s not broken, don’t fix it.” Change the timing belt according to the manufacturer’s maintenance schedule so you don’t waste your money on engine repairs or replacements.

WARNING!!

Often there are no warning signs before a timing belt breaks. But here are some possible indicators that it’s time to replace the timing belt :

Overheat

Vibration or shaking

Reduced engine power

Oil and coolant leakage

Problems with starting the car

Squealing or rubbing belts

Ticking noise coming from the engine

While your vehicle is being repaired, GLOBELT recommends replacing the water pump as well. The water pump usually has the same lifespan and is easy to access when the timing belt is removed. This way, you save your time and money on labor costs.

Why GLOBELT is Your First Choice?

Advantages

Exorbitant Brand Reputation - GLOBELT is a leading supplier of auto transmission system to the automotive vehicle industry.

Warranty - GLOBELT parts are all backed with a minimum of 2 year warranty.

Reasonable Warranty Period - For 100,000 km of usage or 24 month period from the date of purchase whichever comes first.

Great Convenience - Applying warranty via GLOBELT.net by scanning QR code provided.

Excellent Belt Quality -Timing Belt is manufactured with high quality, temperature and contamination resistanceHNBR(Hydrogenated Nitrile Butadiene Rubber).

Outstanding Oil Seal Property - Oil Seal originally sourced from VITON (rubber and fluoropolymer specialist), which well-known for its high temperature resistance.

Conclusion

Timing Belt or belt drives are very common in the industry today. They are used in light as well as heavy-duty applications in many different configurations. Round and toothed belts can measure the slightest relative movement in applications such as motion control, encoders and precision manufacturing. Flat, V and timing belts are widely used as power transmission belts. They find extensive use as material handling equipment too.

Timing Belt or belt drives are preferred in these applications for their salient features such as low cost, low weight, reliability, flexibility, durability, easy installation and maintenance. Generally, they can also be fitted into tight spaces. They do have certain drawbacks though. Often times the belts are not repairable and must be replaced. Their tension needs to be adjusted every now and then. And most belt materials are sensitive to the environment and chemicals such as oils and lubricants. Thus, due consideration and attention must be paid when choosing a belt drive system that is as compatible as possible with the application at hand.

Specialize in all kind of Belt

Our Pages

Contact Us

Follow Us On

© 2024 GloBelt. All Rights Reserved.