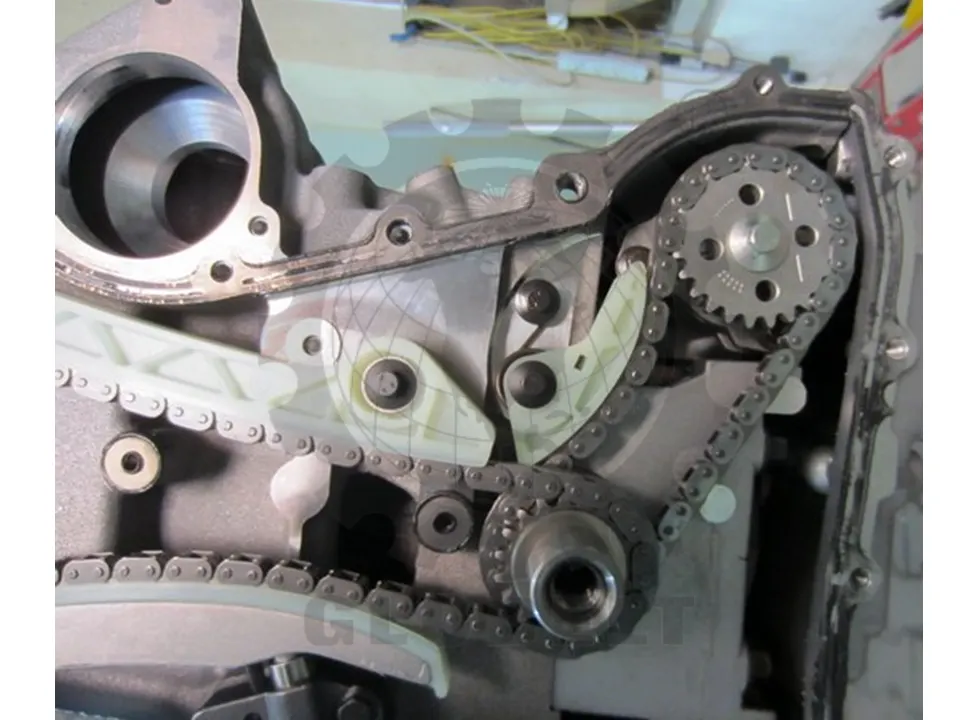

Timing Chain Set

What is Timing Chain Set?

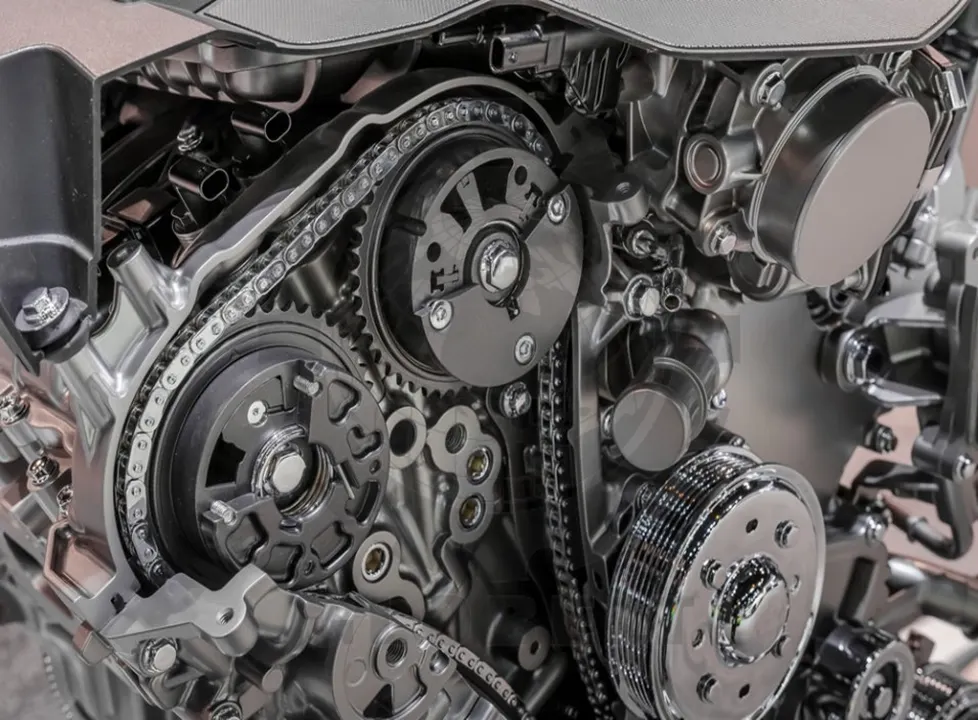

GLOBELT TIMING CHAIN SET is specially design for the convinence of customer when comes to the time for regular replacement of the component. It consists of GLOBELT TIMING CHAIN , TIMING GEAR , TIMING GUIDE , TIMING ADJUSTER PUMP and OIL SEAL , this prefix set of component will help you to be hassle free in changing of timing chains or any other relevant components.

Some repair jobs go hand in hand and it just makes sense to do them together. Timing chains, timing gear, timing guide and timing adjuster pump are just such an example. We've gone even further with this kit and included all engine oil seals to complete the kit.

Components in Timing Chain Set?

Basic

Timing Chain

GLOBELT’s Timing Chainis manufactured withStrong Metallic Property. Timing chain are made up of small pieces of metal joined together, and due to the nature of their construction, timing belts tend to be noisy.

Timing chain may be old technology, but they are proven and they have alonger lifespan because because metal is stronger and resists better.As there is metal on metal contact the timing chain runs through the inside the engine so it can be lubricated by engine oil.

Timing Gear

Timing Gearstructure comprises a wheel disc, a plurality of gear teeth are respectively arranged on the edge around the wheel disc, a step hole is reserved in the middle of the wheel disc, a plurality of positioning holes are reserved on the front face.

Timing gear can bepositioned and prevented from shaking, and on the other hand, vibration generated during rotation of the timing gear is reduced,and normal transmission work is guaranteed.

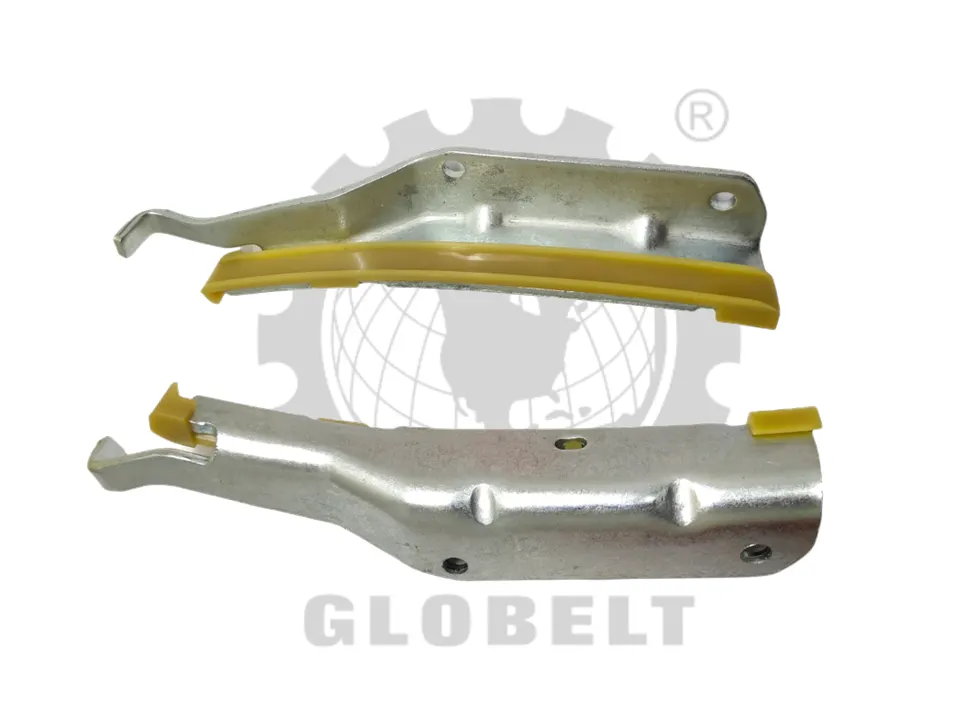

Timing Guide

GLOBELT Timing Guide which are available in Timing Chain Kit is manufactured using premium materials.GLOBELTutilize the latest in design and material technology, ensuring quiet and maintenance.

To call some timing chain guides plastic is not accurate. The materials used by manufacturers are highly engineeredresinsandstructural fibers. These materials are designed to withstand high temperatures and forces inside the engine. They are also engineered to withstand engine oil and harmful vapors created by blowby inside the combustion chamber. The engineered materials are also designed to endure thousands of heat cycles.

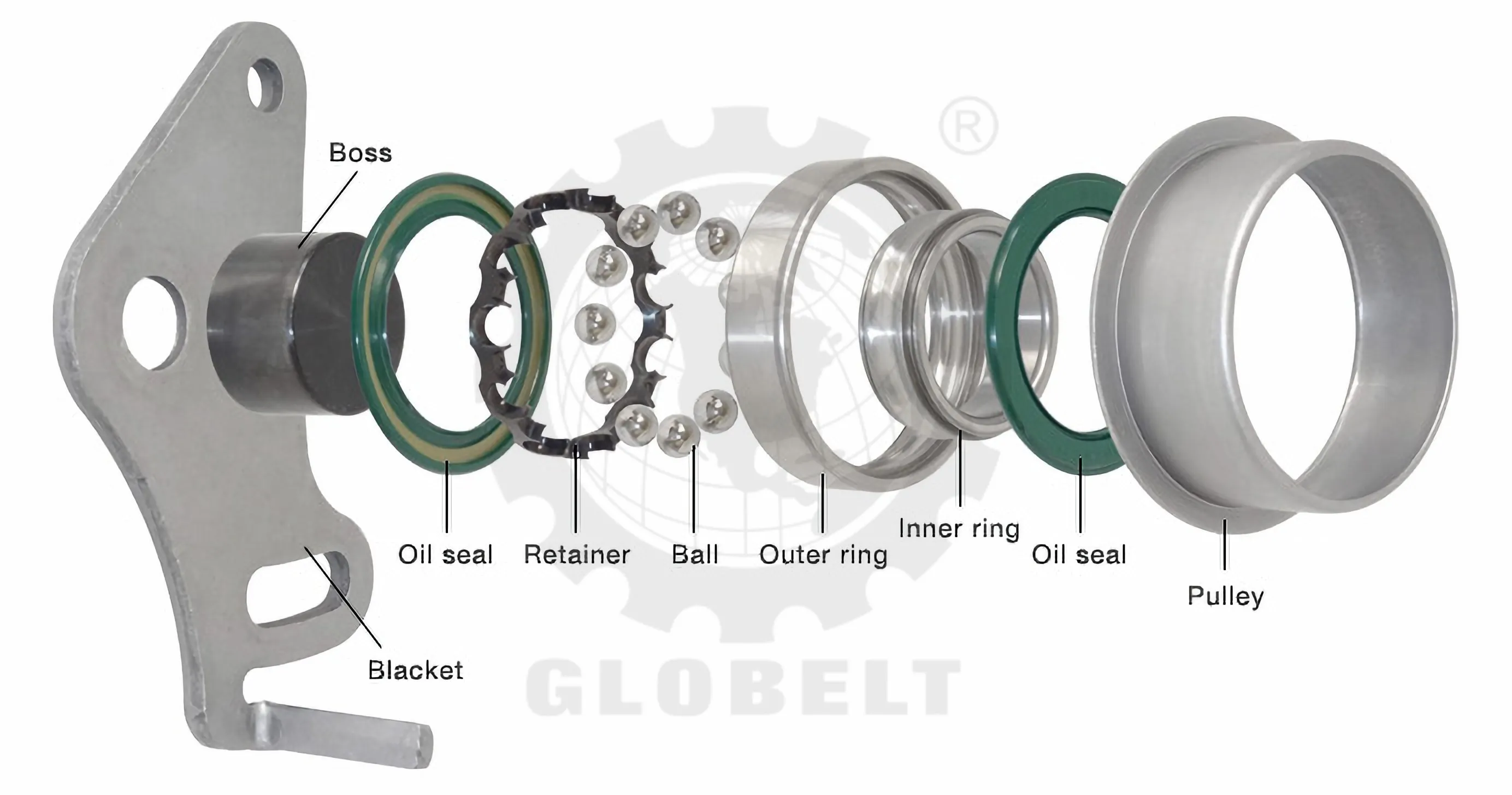

Timing Adjuster Pump

Timing Adjuster Pumpis a high precision element designed to optimize chain tension quickly and efficiently. It consists of a base, tensioner arm, spring, and pulley is widely used in belt drive system.

In Timing Chain Kit, timing adjuster pump is in the cylinder block. When the chain is driven, it provides the necessarytension, absorb shock and vibrationof the chain.

Oil Seal

Oil Sealoriginally sourced fromVITON, which well-known for its high temperature resistance.

VITON (rubber and fluoropolymer specialist) is a synthetic rubber and fluoropolymer elastomer used in O-rings, seals and other moulded products.Genuine Viton®is manufactured from100% pure fluoroelastomersand is certified with theViton® certificate.

Specific

Specific Component - all the components of current section only included in some specific car model.

Oil Pump Chain

GLOBELT’s Oil Pump Chain is manufactured with Strong Metallic Property . Oil pump chain are made up of small pieces of metal joined together, and due to the nature of their construction, timing belts tend to be very noisy.

Oil pump chain is work with oil pump to ensure continuous flow rates and maintain engine lubrication and will stretch over time.

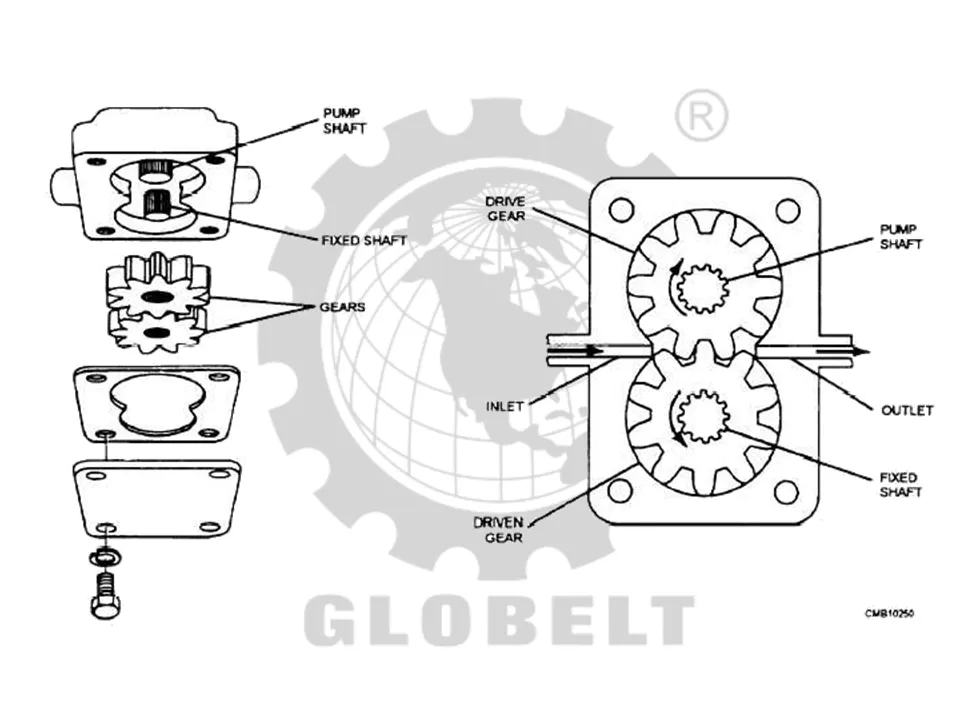

Oil Pump Gear

Oil Pump Gear structure comprises a wheel disc, a plurality of gear teeth are respectively arranged on the edge around the wheel disc, a step hole is reserved in the middle of the wheel disc, a plurality of positioning holes are reserved on the front face.

Timing gear can bepositioned and prevented from shaking, and on the other hand, vibration generated during rotation of the timing gear is reduced,and normal transmission work is guaranteed.

Oil pump circulates engine oil under pressure to the rotating oil pump gears. This lubricates the gears, allows the use of higher-capacity fluid gears and also assists in cooling the engine.

Oil Pump Guide

GLOBELT Oil Pump Guidewhich are available in Timing Chain Kit is manufactured using premium materials. GLOBELT utilize the latest in design and material technology, ensuring quiet and maintenance.

Function of Basic Component & Specific Components of Timing Chain Set

Basic Component

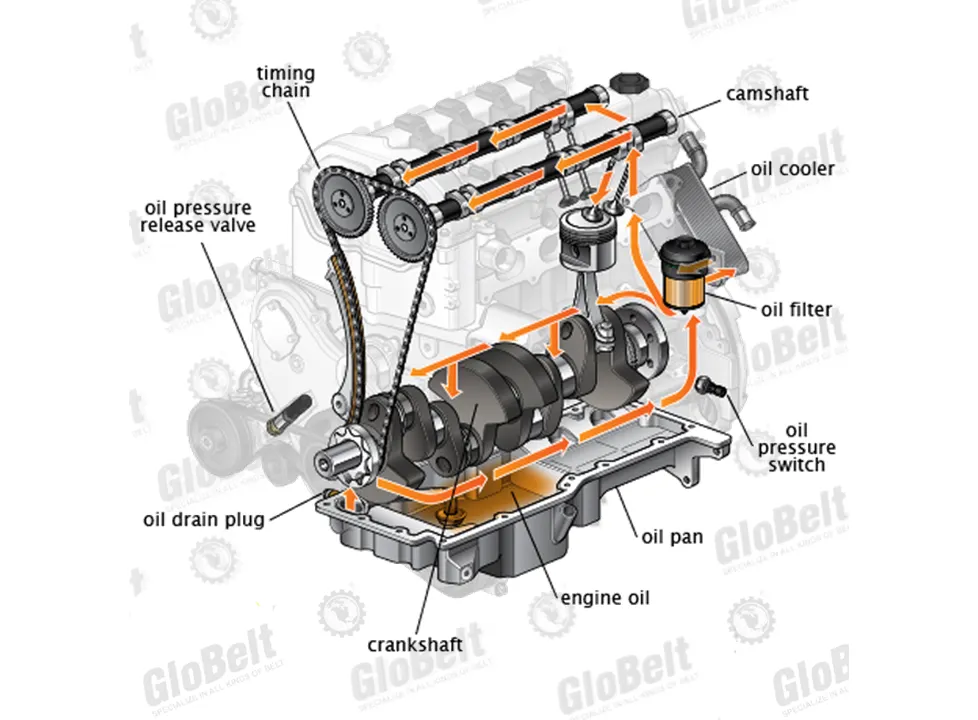

Timing Chain

A Timing Chain is an internal engine component that's fitted to synchronize the rotation of the camshaft and the crankshaft, these two elements are essential for driving the wheels. This synchronization ensures that the engine's valves open and close at the correct times in relation to the position of the pistons. The movement of the chain allows for engine cylinders to produce power to operate and propel the vehicle.

Just like belts, a timing chain is another method of transmitting mechanical power from one point to another. But it’s often used to convey power to the wheels of vehicles. Timing chain are also called a drive chain or transmission chain that often conveys power by a roller chain passing over a sprocket gear with teeth. These teeth mesh with the holes in the chain links. Some chains, to help installation, maintenance or replacement operations, have signaling links that offer visual aid for the correct positioning.

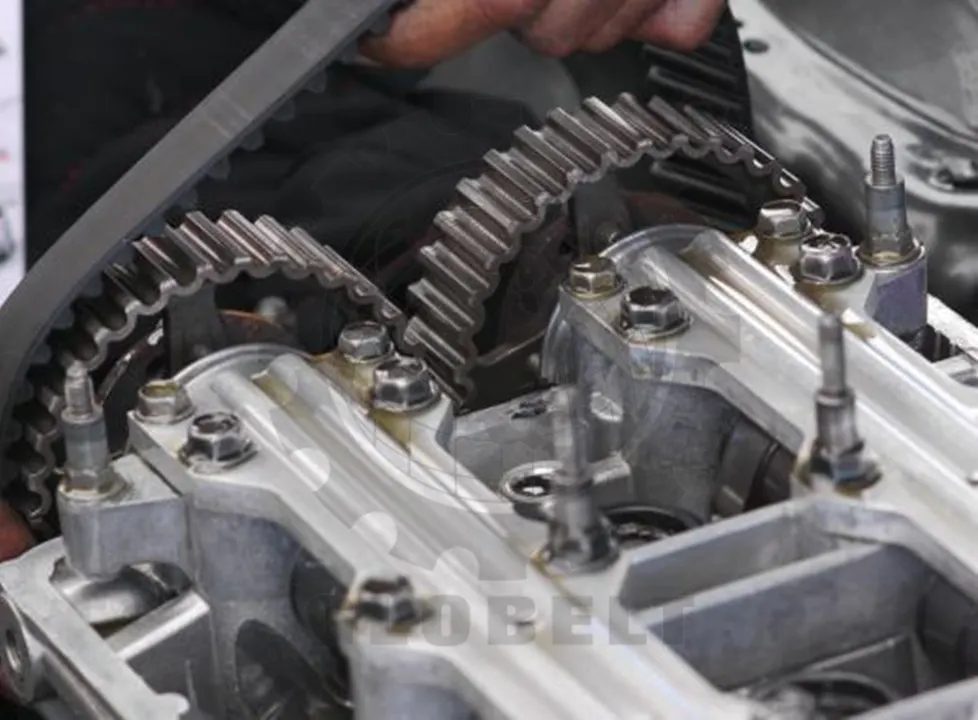

How does Timing Chain work?

The timing chain synchronises the opening and closing of the engine valves, known as intake and exhaust valves. It allows them to move at the required intervals to allow for the appropriate amount of fuel to enter the engine, and for exhaust to exit the engine. The process produces the exact amount of internal combustion required to drive at the desired speed.

Highlights

Timing Chain ensures precise synchronize opening and closing of the engine’s valves.

It connects the crankshaft and the camshaft together to control the valve operation.

Located inside the engine.

Needs to be lubricated by the oil in the engine.

Oil maintenance important as well to maintain the health of timing chain.

A timing chain is just a single device but connects different parts such as the timing gear, timing guide, timing adjuster pump, oil seal, oil pump chain, oil pump gear and oil pump guide.

Timing Gear

The purpose of Timing Gear is to allow the camshaft and crankshaft to turn the timing chain. The crankshaft turns to move pistons up and down inside the cylinders. The camshaft turns to allow intake and exhaust valves on the cylinders to open and close. These components are important for proper engine timing.

As the piston moves downward inside the cylinder, the intake valves open to allow fuel and air into the cylinder. As the piston moves upward inside the exhaust the exhaust valves open to expel exhaust valves from the cylinders. If the intake valves are not opening and closing properly, the correct air/fuel mixture will be unable to enter and remain inside the cylinders. If the exhaust valves are not opening and closing properly, exhaust gases will be trapped inside the cylinder.

Highlights

To provide chain with tension.

To transfer driving force from crankshaft.

To prevent chain slippage.

To minimize space of chain layout.

Where the Timing Gear placed?

The timing gear is connected by chain, gears, or a belt to the crankshaft at one end and the camshaft on the other. It is marked with tiny increments all around its perimeter, which correspond to degrees of timing from the straight-up timing position of the camshaft and crankshaft. These marks assist the individual who is tuning up the engine to set the timing to the determined optimal timing degrees of the camshaft and engine designers.

While the gear rotates a full 360 degrees, the timing marks are concerned with just a few degrees before and after top dead center of the piston's rotation. Top dead center is when the piston is at its absolute highest point of travel within the cylinder or at the top of the stroke at the dead center of when the crankshaft is neither traveling up nor down in the cylinder. The gear is used to measure the amount of rotation in degrees in relation to when the valves begin to open and close.

Timing Guide

A Timing Guide serves as a track or guide, for the timing chain, connecting the crankshaft and camshaft. Timing chain guides are often the best indicators of the health of the timing chain, sprockets and the entire engine. Any abnormal noises or correlation codes need to be taken seriously. A timing chain guide is designed to keep the chain in tension so it will not flutter like a serpentine belt when the engine speed changes.

Abnormal wear patterns indicate a chain system problem like endplay in the crankshaft and camshaft or other sprockets. Wear patterns can also indicate if the tensioners and oil pressure are operating properly. Timing chain guides are designed to wear, but the guides are designed to last the engine’s life. If the guides wear prematurely, it is a sign that the path of the chain, lubricants or tensioners are not performing as they should.

Highlights

Timing Guide indicators of the health of the timing chain.

Designed to keep the chain in tension.

Located inside the engine.

Indicate if the tensioners and oil pressure are operating properly.

It's materials are designed to withstand high temperatures and forces inside the engine.

It also engineered to withstand engine oil and harmful vapors

What causes Timing Guide break?

When a timing chain guide breaks or cracks, it indicates a lack of maintenance, high miles, or a failed component. For some applications, a failed tensioner will cause timing chain slap that can damage the guide. Other mechanical items can hasten a timing chain failure, like multiple overheating incidents or blocked oil passages in the top end of the engine.

Timing Adjuster Pump

The Timing Adjuster Pump is a high precision element designed, as its name suggests, to optimize chain tension quickly and efficiently. The majority of timing chain tensioners use oil pressure to take up slack in the chain. Like the guides, a tensioner will age prematurely as old oil degrades the seals and clogs the oil passages.

The typical timing adjuster pump assembly consists of a housing, spring and ratcheting plunger. The plunger is locked into the housing to prevent the accidental release of the spring before or during installation. The timing adjuster pump ensures the correct and necessary tension of the timing chain that surrounds the crankshaft sprocket and the camshaft sprocket. It exerts full control, making the chain run smoothly, preventing it from rattling and coming off the sprockets. In addition, it protects other elements such as alternators or water pumps against failure.

Highlights

Timing Adjuster Pump optimize chain tension quickly and efficiently.

Preventing chain from rattling and coming off the sprockets.

It protects other components.

Use oil pressure to take up slack in the chain.

What signals show timing adjuster pump damage?

Is a fact that chains will stretch due to use and over time. Wear and tear cause increase of vibration and besides causes wear on other components such as the chain tensioner.

There are some signals that can warn of a tensioner malfunction and, as such and as further explained below, will advise the user of the presence of a failing timing chain system so that they can take appropriate action.

Rattling noise from vehicle engine.

Loss of engine power.

Problems when starting.

Oil Seal

Oil seals, often called a rotary shaft seal or grease seal, closes the gap between stationary and moving components in mechanical equipment (most often rotating shafts), helping prevent lubricant escape and stopping harmful materials , such as dirt, from moving in through the clearance. Oil seals are most commonly used in gearboxes, hydraulic cylinders, and related components.

It plays a key role in all moving parts of an engine, acting as a physical barrier. This mechanical seal fulfils the dual purpose of sealing a rotary shaft to maintain the necessary lubrication (avoiding leaks) and preventing other foreign matter from contaminating shafts and bearings in the rotary shaft equipment.

Highlights

To prevent lubricants from leaking outside the seal even under high pressure.

To act as a barrier to retain the lubricating oil.

To prevent dirt and other contaminants from entering the unit.

Characteristics of Oil Seal

A.Nose gasket prevents leakage through the seal O.D.

B.Lip design with excellent followability.

C.Linear contact type sealing adge with high durability under high peripheral spped.

D. Rubber material with high self-lubricating property.

Specific Component

Oil Pump Chain

The Oil Pump Chain is the part of the oil pump which lubricates various engine components like pistons, pins, camshafts, crankshaft, bearings. The pump supplies oil to these parts to minimize the friction and heat which is generated due to their constant range of motion when the engine is running.

The pump greatly helps in engine cooling and prevents overheating. The oil pump chains are of heavy-grade metal alloys like stainless steel and bronze forged steel and are shaped in roller and sleeves to fit perfectly with the oil pump's teeth.

Highlights

Helps circulation of engine oil.

Allow the uses of high-capacity fluid bearings.

Enhances engine cooling

Causes of a bad quality oil pump chain

Excessive temperature

Corrosion

Dirt and debris

Cheap quality manufacturing material

Symptoms of a bad quality oil pump chain

Glowing engine indicator

Fumes releasing from the bonnet area

Engine overheating

Cracking noises

Oil Pump Gear

An Oil Pump Gear draws in and expels oil to supply the lubrication oil to the internal combustion engine. The primary function of the oil pump is to provide pressurized circulation of engine oil to the bearings, pistons, and camshaft.

This helps lubricate bearings with a higher capacity and contributes to the engine's cooling system. So the oil is supplied into the pump discharge tube after being trapped between the lobes. Additionally, a pressure relief valve is crucial for the rotor type oil pump.

Highlights

Circulates engine oil.

Assists in engine cooling.

Reduces friction.

Lubricates the engine parts.

Removes debris.

Causes of faulty oil pump gears

High-pressure level

Engine overheating

Change in temperature

Poor quality engine oil

Head gasket failure

Symptoms of faulty oil pump gears

Black smoke emission

Oil leakage

Ticking noises from the pump

Oil Pump Guide

Oil Pump Guides are often the best indicators of the health of the oil pump chain, sprockets and the entire engine. Any abnormal noises or correlation codes need to be taken seriously. A oil pump guide is designed to keep the chain in tension so it will not flutter like a serpentine belt when the engine speed changes.

Oil pump guides are designed to wear, but the guides are designed to last the engine’s life. If the guides wear prematurely, it is a sign that the path of the chain, lubricants or tensioners are not performing as they should.

Highlights

Oil Pump Guide indicators of the health of the oil pump chain.

Designed to keep the chain in tension.

Located inside the engine.

Indicate if the tensioners and oil pressure are operating properly.

It's materials are designed to withstand high temperatures and forces inside the engine.

It also engineered to withstand engine oil and harmful vapors

What causes Oil Pump Guide break?

When a oil pump guide breaks or cracks, it indicates a lack of maintenance, high miles, or a failed component. For some applications, a failed tensioner will cause timing chain slap that can damage the guide. Other mechanical items can hasten a timing chain failure, like multiple overheating incidents or blocked oil passages in the top end of the engine.

Warning Signs - Maintenance & Replacement

How does Timing Chain break?

The timing belt break more often because of a age. Just imagine what is happening to that chain as it spins in your engine at 4000 rpm. Timing is everything and the chain is the key timekeeper. At some point they just wear out no matter what you do to maintain. If you have an engine with a chain that has already gone 150,000 miles replace it for peace of mind and financial security.

Another cause of the breakdown of the timing chain component is failure of plastic guide rails. This relates specifically to the V8 gas engines but can also apply to other engines. It is common for the upper guide rails to break off. In some cases the plastic can get sucked up into the sprocket and cause the chain to jump timing. We have new upgraded genuine guide rails available along with instructions on how to install them. Don't neglect this to the peril of your engine.

What happens when the timing chain breaks?

The engine's timing will be messed up resulting in piston and valve collision.

Engine stops running. This can only be rectified with a very expensive general overhaul.

If the car is driven fast when the chain breaks, the engine block may crack. This would be very expensive to fix as it results in a total engine replacement.

Maintenance & Replacement of Timing Chain

Unless there is a specific fault, the timing chain should be replaced between 80,000 and 120,000 miles. Chain problems are frequent in automobiles with increasing mileage. If you’re driving an older car or one with a lot of miles on it, keep an eye out for signs that the timing chain is failing. Because the timing chain might break and require replacement, it’s critical to be able to spot the symptoms and have it serviced before it completely fails.

It is important for checking the oils levels of engine and changing them every year or after some milage is crucial for vehicle to keep the timing chain in good condition. Lubricating oil is essential keep the chain clean, as dirt (dust, rust, metal residues) is collected by the fluid, preventing the chain links from deteriorating due to excessive frictions.

WARNING!!

Often there are no warning signs before a timing chain breaks. But here are some possible indicators that it’s time to replace the timing chain :

Rattling noise from engine

Engine vibrates badly

Engine misfires and sluggishness

Difficult to start the engine

Check engine light illuminated

When the engine is idling, it vibrates or shakes

The signs of metal fatigue as flakes of metal in the oil

Despite wanting to save money, it’s recommended that you do not fit a timing chain yourself. A poorly fitted timing chain can have serious consequences, and you may damage your engine in the process of attempting repairs.

Why GLOBELT is Your First Choice?

Advantages

Exorbitant Brand Reputation - GLOBELT is a leading supplier of auto transmission system to the automotive vehicle industry.

Warranty - GLOBELT parts are all backed with premium warranty.

Great Convenience - Applying warranty via GLOBELT.net by scanning QR code provided.

OE Quality Standard - GLOBELT Timing Chain Set meet all OE quality standards and include all components required for a professional repair.

Outstanding Oil Seal Property - Oil Seal originally sourced from VITON (rubber and fluoropolymer specialist), which well-known for its high temperature resistance.

Conclusion

Timing chains are being used more and more in modern engines. They are more durable and usually do not have a recommended replacement interval. Although the timing chain does not require maintenance per se, it does require constant lubrication. The engine does this normally as it runs. However, low oil level or using a poor-quality oil will keep the timing chain from being properly lubricated. A timing chain can last a few hundred thousand miles with regular oil changes using high quality oil.

The very nature of a chain unit means that failure often means total calamity. If the chain breaks, the part will no longer do its job and, unfortunately, the car will no longer be able to run since the chain is a heavy metal piece, which, if it breaks, can damage the engine block, the cylinder head, and even bend the crankshaft. Usually, if the chain breaks, you will likely need a completely new engine.

Specialize in all kind of Belt

Our Pages

Contact Us

Follow Us On

© 2024 GloBelt. All Rights Reserved.